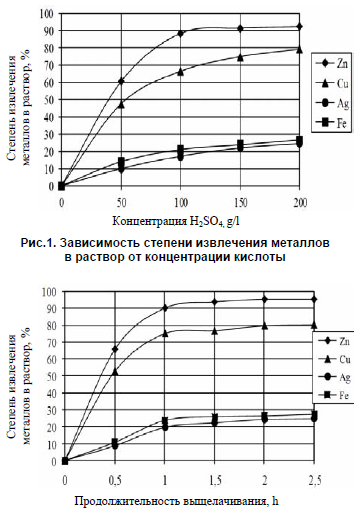

Maqolada rux va bir qancha qimmatbaho metallarni ajratib olish uchun rux keklarini suv bug`i ishtirokida termik ishlov berish usuli masalalari ko ׳rib chiqilgan. 2 soat davomida oltingugurt kislotasininq konsentratsiyasi 125-150 g/l,issiqligi 75-800C termik bug ׳i bilan ishlov berilgan rux keklarini ishqorlash samarali masalalari aniqlangan. Eritmadagi ruh ishlab chiqarish darajasi 85-95 % ni va temir 28,1 % ni, kekni chiqishi esa qoldiq og`irligidan 58-60 % ni tashkil etadi. Olib borilgan ilmiy-tadqiqot ishi natijalari keyingi oltingugurt kislotali ishqorlash rux keklarni samarali ishlab chiqarish imkoniyatini beradi.

Tayanch iboralar: rangli metallar, ruh ishlab chiqarish keki, getit, termik bug bilan ishlov berish, qoldiq , ׳ishqorlashning optimal sharoitlari, chiqarish darajasi, oltingugurt kislotasi, konsentratsiya, eritma, pishirish, parchalanish,oksidlanish.

The efficient processing of zinc cake by thermocouple method, for additional recovery of zinc and other nonferrous metall. Install optimal conditions of leaching thermocouple treated zinc cakes at a sulfuric acid concentration of 125-150 g/l, temperature of 75-800S and duration 2 hours. The degree of extraction of zinc in the solution is 85-95 % and ferrum 28,1 %, and the yield of cake 58-60 % of weight cinder. These findings enable efficient processing of zinc cakes, followed by sulfuric acid leaching.

Key words: non-ferrous metals, zinc cake production, goethite, thermocouple treated method calcine, the optimum leaching conditions, the degree of extraction, sulfuric acid, the concentration of the solution, roasting, decomposition, oxidation.